Open Access

Original Article

Digital analysis of internal fit variation of additively manufactured crown patterns

Aim:

The purpose of this study was to digitally quantify the consistency and variation of printed resin crown patterns produced by different 3D printers, aiming to evaluate their clinical relevan

[...] Read more.

Aim:

The purpose of this study was to digitally quantify the consistency and variation of printed resin crown patterns produced by different 3D printers, aiming to evaluate their clinical relevance and accuracy. This was accomplished by evaluating patterns manufactured using three different 3D printers and resin materials, assessing their fit and adaptation through digital scanning and analysis. The objective was to determine the internal and marginal variations of printed crown resin patterns and to identify the printer and material combinations that produce the most consistent and clinically acceptable results.

Methods:

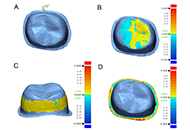

A prefabricated typodont tooth was prepared for a crown and scanned using an intraoral scanner. From this scan, a crown was designed and the resulting STL file was exported. This 3D file was manufactured using resins indicated for castable patterns on 3 different printers: FotoDent® Cast with the Carbon M2 printer, Form 3 Castable with the Form 2 printer, and Siraya Tech Cast with the ELEGOO Mars 2 Pro 3D printer. Finally, the crown resin patterns were scanned using an intraoral digital scanner (3Shape TRIOS 3) scanner, and crown adaptation was digitally quantified in GeoMagic software. Clinically relevant significance was determined (marginal gap < 50 µm) between resin patterns printed on different printers.

Results:

Form 3 Castable/Form 2 printer had the lowest mean internal variation at all measurement areas, 21.07 μm at the occlusal, 104.23 μm at the margin, and 37.98 μm at the axial. FotoDent® Cast/Carbon M2 had the largest marginal variation while Siraya Tech Cast/ELEGOO Mars 2 Pro had the largest occlusal variation. Within each material, the largest internal variation was at the marginal area while the lowest value was in the occlusal area.

Conclusions:

All printed crowns displayed clinically acceptable ranges, but there was a statistically significant difference in the fit between all printers.

Wendy A. Clark ... Ingeborg J. De Kok

View:1528

Download:50

Times Cited: 0

Aim:

The purpose of this study was to digitally quantify the consistency and variation of printed resin crown patterns produced by different 3D printers, aiming to evaluate their clinical relevance and accuracy. This was accomplished by evaluating patterns manufactured using three different 3D printers and resin materials, assessing their fit and adaptation through digital scanning and analysis. The objective was to determine the internal and marginal variations of printed crown resin patterns and to identify the printer and material combinations that produce the most consistent and clinically acceptable results.

Methods:

A prefabricated typodont tooth was prepared for a crown and scanned using an intraoral scanner. From this scan, a crown was designed and the resulting STL file was exported. This 3D file was manufactured using resins indicated for castable patterns on 3 different printers: FotoDent® Cast with the Carbon M2 printer, Form 3 Castable with the Form 2 printer, and Siraya Tech Cast with the ELEGOO Mars 2 Pro 3D printer. Finally, the crown resin patterns were scanned using an intraoral digital scanner (3Shape TRIOS 3) scanner, and crown adaptation was digitally quantified in GeoMagic software. Clinically relevant significance was determined (marginal gap < 50 µm) between resin patterns printed on different printers.

Results:

Form 3 Castable/Form 2 printer had the lowest mean internal variation at all measurement areas, 21.07 μm at the occlusal, 104.23 μm at the margin, and 37.98 μm at the axial. FotoDent® Cast/Carbon M2 had the largest marginal variation while Siraya Tech Cast/ELEGOO Mars 2 Pro had the largest occlusal variation. Within each material, the largest internal variation was at the marginal area while the lowest value was in the occlusal area.

Conclusions:

All printed crowns displayed clinically acceptable ranges, but there was a statistically significant difference in the fit between all printers.

Digital analysis of internal fit variation of additively manufactured crown patternsOpen AccessOriginal ArticleAim: The purpose of this study was to digitally quantify the consistency and variation of printed resin crown patterns produced by different 3D printers, aiming to evaluate their clinical relevan [...] Read more.Wendy A. Clark ... Ingeborg J. De KokPublished: October 14, 2024 Explor BioMat-X. 2024;1:280–288

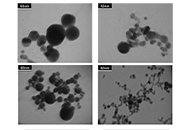

Digital analysis of internal fit variation of additively manufactured crown patternsOpen AccessOriginal ArticleAim: The purpose of this study was to digitally quantify the consistency and variation of printed resin crown patterns produced by different 3D printers, aiming to evaluate their clinical relevan [...] Read more.Wendy A. Clark ... Ingeborg J. De KokPublished: October 14, 2024 Explor BioMat-X. 2024;1:280–288 Spectrum reconstruction of experimentally produced nano-colloids using Mie theoryOpen AccessOriginal ArticleAim: Synthesis of plasmonic nanoparticles, characterization, size detection by modeling. Methods: Colloidal plasmonic gold and silver nanoparticles were prepared by laser ablation with a 1, [...] Read more.Hamid Nadjari, Hadi MovahedinejadPublished: October 22, 2024 Explor BioMat-X. 2024;1:289–299

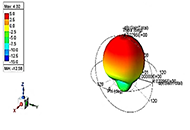

Spectrum reconstruction of experimentally produced nano-colloids using Mie theoryOpen AccessOriginal ArticleAim: Synthesis of plasmonic nanoparticles, characterization, size detection by modeling. Methods: Colloidal plasmonic gold and silver nanoparticles were prepared by laser ablation with a 1, [...] Read more.Hamid Nadjari, Hadi MovahedinejadPublished: October 22, 2024 Explor BioMat-X. 2024;1:289–299 3D printed hernia mesh implant: a conformability studyOpen AccessOriginal ArticleAim: This study aims to explore the sensing capabilities of polyvinylidene fluoride-hydroxyapatite-chitosan (PVDF-HAP-CS) composite-based hernia mesh implants (of conformal/planar design), follow [...] Read more.Abhishek Barwar ... J. Paulo DavimPublished: September 30, 2024 Explor BioMat-X. 2024;1:266–279

3D printed hernia mesh implant: a conformability studyOpen AccessOriginal ArticleAim: This study aims to explore the sensing capabilities of polyvinylidene fluoride-hydroxyapatite-chitosan (PVDF-HAP-CS) composite-based hernia mesh implants (of conformal/planar design), follow [...] Read more.Abhishek Barwar ... J. Paulo DavimPublished: September 30, 2024 Explor BioMat-X. 2024;1:266–279 Advancements in surface modification strategies of vascular grafts to improve biocompatibility and tissue integrationOpen AccessReviewImproving the performance of blood-contacting medical implants is a global health necessity aimed at reducing mortality and morbidity in patients with cardiovascular diseases. Surface modification o [...] Read more.Noor Abu Jarad ... Tohid F. DidarPublished: September 13, 2024 Explor BioMat-X. 2024;1:241–265

Advancements in surface modification strategies of vascular grafts to improve biocompatibility and tissue integrationOpen AccessReviewImproving the performance of blood-contacting medical implants is a global health necessity aimed at reducing mortality and morbidity in patients with cardiovascular diseases. Surface modification o [...] Read more.Noor Abu Jarad ... Tohid F. DidarPublished: September 13, 2024 Explor BioMat-X. 2024;1:241–265