Editor's Picks

Articles

Latest

Most Viewed

Most Downloaded

Most Cited

Open Access

Perspective

Can fracture non-union be predicted using deep learning?

Ali Yüce ... Abdülhamit Misir

Published: April 08, 2025 Explor Musculoskeletal Dis. 2025;3:100790

This article belongs to the special issue Innovation in Orthopedics

Open Access

Original Article

The prevalence and risk factors of gouty arthritis among fishermen in the Niger Delta region of Nigeria

Gogo James Owo ... Enyohwo Dennis Kpomah

Published: March 25, 2025 Explor Musculoskeletal Dis. 2025;3:100789

Open Access

Review

Urate lowering therapy in primary care: rheum for improvement

Emilie Schurenberg ... Kenneth G. Saag

Published: March 25, 2025 Explor Musculoskeletal Dis. 2025;3:100788

This article belongs to the special issue Pharmacological and Non-Pharmacological Management of Gout

Open Access

Commentary

Highly effective treatment options for rheumatoid arthritis afforded by the availability of biosimilars

Leticia A. Shea, Jamshaid S. Ahmed

Published: March 03, 2025 Explor Musculoskeletal Dis. 2025;3:100787

This article belongs to the special issue Biosimilars: State of the Art in the Treatment of Rheumatic Diseases

Open Access

Commentary

Re-conceptualizing structural damage in chronic calcium pyrophosphate crystal inflammatory arthritis through ultrasonography: a pictorial essay

Janeth Yinh ... Ali Guermazi

Published: February 24, 2025 Explor Musculoskeletal Dis. 2025;3:100786

This article belongs to the special issue Multifaceted Imaging in Rheumatic and Musculoskeletal Diseases

Open Access

Perspective

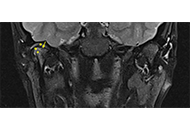

Perspective on clinical and imaging tools for early identification of temporomandibular joint involvement in juvenile idiopathic arthritis

Silvia Magni-Manzoni

Published: February 11, 2025 Explor Musculoskeletal Dis. 2025;3:100785

This article belongs to the special issue Multifaceted Imaging in Rheumatic and Musculoskeletal Diseases

Open Access

Case Report

Similarities and differences between gouty arthritis and rheumatoid arthritis—an interesting case with a short look into the literature

David Kiefer ... Juergen Braun

Published: February 24, 2023 Explor Musculoskeletal Dis. 2023;1:11–19

Open Access

Case Report

Physiotherapy management of a patient with neck pain having block vertebra: a case report

Sarah Quais, Ammar Suhail

Published: March 27, 2023 Explor Musculoskeletal Dis. 2023;1:31–36

Open Access

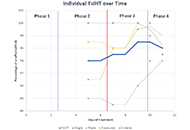

Case Report

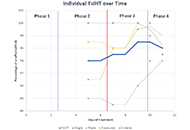

Return-to-play decision-making following ankle injury: a comprehensive case analysis of the functional hop test

Michael Crinion ... Michael Agnone

Published: March 06, 2024 Explor Musculoskeletal Dis. 2024;2:75–81

Open Access

Review

Premature mortality with gout and hyperuricemia may be reduced by early resolution of comorbid obstructive sleep apnea

Burton Abrams

Published: August 31, 2023 Explor Musculoskeletal Dis. 2023;1:106–120

This article belongs to the special issue Hyperuricemia current state and prospects

Open Access

Review

Is there a place for magnetic resonance imaging in diffuse idiopathic skeletal hyperostosis?

Iris Eshed

Published: April 27, 2023 Explor Musculoskeletal Dis. 2023;1:43–53

This article belongs to the special issue Diffuse Idiopathic Skeletal Hyperostosis- A common but neglected disease

Open Access

Review

Diffuse idiopathic skeletal hyperostosis, beyond the musculoskeletal system

Fabiola Atzeni ... Reuven Mader

Published: December 04, 2023 Explor Musculoskeletal Dis. 2023;1:216–227

This article belongs to the special issue Diffuse Idiopathic Skeletal Hyperostosis- A common but neglected disease

Open Access

Review

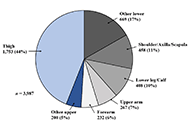

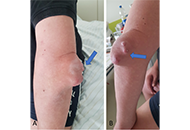

Soft tissue sarcoma: clinical recognition and approach to the loneliest cancer

Sujan Shakya ... Xiang Zhou

Published: February 06, 2024 Explor Musculoskeletal Dis. 2024;2:56–68

Open Access

Review

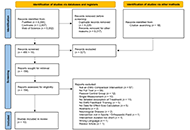

Interstitial lung disease in patients with rheumatoid arthritis: a narrative review

Gloria Candelas Rodríguez, Virginia Villaverde

Published: October 20, 2023 Explor Musculoskeletal Dis. 2023;1:128–142

This article belongs to the special issue Comorbidities in rheumatoid arthritis

Open Access

Case Report

Similarities and differences between gouty arthritis and rheumatoid arthritis—an interesting case with a short look into the literature

David Kiefer ... Juergen Braun

Published: February 24, 2023 Explor Musculoskeletal Dis. 2023;1:11–19

Open Access

Case Report

Return-to-play decision-making following ankle injury: a comprehensive case analysis of the functional hop test

Michael Crinion ... Michael Agnone

Published: March 06, 2024 Explor Musculoskeletal Dis. 2024;2:75–81

Open Access

Review

Uric acid in atherosclerosis and cardiovascular diseases: innocent bystander or ruthless killer?

Giovanni Cimmino ... Plinio Cirillo

Published: June 03, 2024 Explor Musculoskeletal Dis. 2024;2:189–207

This article belongs to the special issue Hyperuricemia: current state and prospects

Open Access

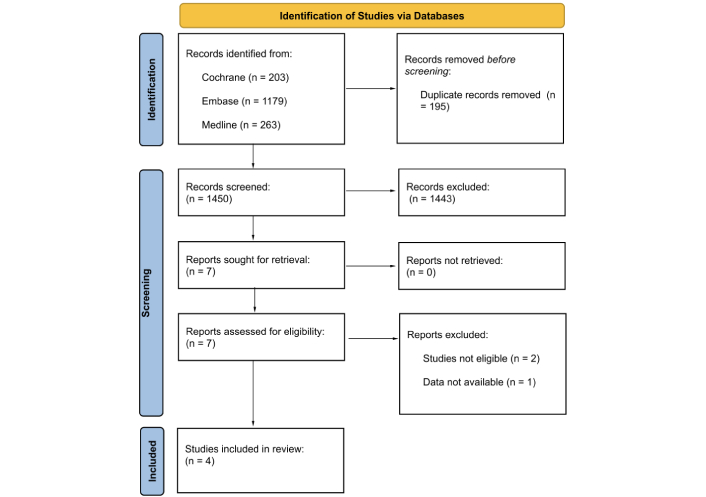

Systematic Review

Role and effectiveness of surface EMG feedback in sports and orthopedic rehabilitation: a systematic review

Thomas Haab ... Paul Burkey

Published: September 12, 2024 Explor Musculoskeletal Dis. 2024;2:391–407

Open Access

Review

How should we do in the selection and follow-up of systemic conventional treatments in psoriasis?

Sevgi Akarsu

Published: December 05, 2023 Explor Musculoskeletal Dis. 2023;1:241–256

Open Access

Review

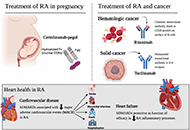

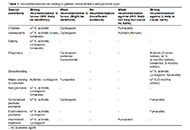

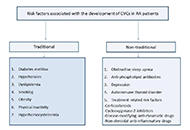

Rheumatoid arthritis and cardiovascular comorbidities

Uğur Özkan ... Murat Birtane

Published: December 06, 2023 Explor Musculoskeletal Dis. 2023;1:264–288

This article belongs to the special issue Comorbidities in rheumatoid arthritis

Open Access

Review

Interstitial lung disease in patients with rheumatoid arthritis: a narrative review

Gloria Candelas Rodríguez, Virginia Villaverde

Published: October 20, 2023 Explor Musculoskeletal Dis. 2023;1:128–142

This article belongs to the special issue Comorbidities in rheumatoid arthritis

Open Access

Review

Work-related musculoskeletal disorders among surgeons: a bibliometric analysis from 1982 to 2024

Philippe Gorce, Julien Jacquier-Bret

Published: July 30, 2024 Explor Musculoskeletal Dis. 2024;2:317–335

This article belongs to the special issue Prevalence and Risk Factors of Work-related Musculoskeletal Disorders

Open Access

Review

Psoriasis, bone and bowel: a comprehensive review and new insights

Fakhreddin Sabooniha

Published: January 18, 2024 Explor Musculoskeletal Dis. 2024;2:1–19

Open Access

Review

Diffuse idiopathic skeletal hyperostosis and axial spondyloarthritis—similarities and differences

David Kiefer ... Xenofon Baraliakos

Published: November 20, 2023 Explor Musculoskeletal Dis. 2023;1:194–206

This article belongs to the special issue Diffuse Idiopathic Skeletal Hyperostosis- A common but neglected disease

Special Issues

Ongoing Special lssues

Completed Special lssues

Innovation in Orthopedics

Prof. Ashok N. Johari Prof. Philippe Hernigou

October 31, 2025

Published Articles: 1

Evaluation and Outcomes in the Management of Gout

Prof. Fernando Pérez-Ruiz

October 31, 2025

Published Articles: 0

Macrophages and Fibrosis in the Rheumatic Diseases: from Pathophysiology to Treatment

Dr. Stefano Soldano

August 31, 2025

Published Articles: 0

Ultrasound as Outcome Measure in Rheumatic Diseases Trials

Dr. Andrea Di Matteo

August 31, 2025

Published Articles: 0

Biosimilars: State of the Art in the Treatment of Rheumatic Diseases

Prof. Valderilio Feijó Azevedo

August 31, 2025

Published Articles: 6

Multifaceted Imaging in Rheumatic and Musculoskeletal Diseases

Dr. Peter Mandl

August 31, 2025

Published Articles: 3

Pharmacological and Non-Pharmacological Management of Gout

Prof. George Nuki

January 31, 2025

Published Articles: 8

Prevalence and Risk Factors of Work-related Musculoskeletal Disorders

Prof. Philippe Gorce

August 31, 2025

Published Articles: 3

Cell Therapy and Tissue Engineering for Musculoskeletal Conditions: From Pre-clinical Studies to Clinical Trials

Prof. Elena Jones

March 31, 2024

Published Articles: 1

Calcium Pyrophosphate Deposition Disease

Prof. Jürgen Braun

August 31, 2025

Published Articles: 6

Hyperuricemia: current state and prospects

Dr. Blanka Stiburkova

August 31, 2024

Published Articles: 2

Journal Information

Journal Indexing

Journal Metrics

Article Usage (total)

Views: 164,550

Downloads: 2,796

Title: Unravelling the interplaybetween #Harmattan wind andbaroreflex functions: implicationon environmental health andcardiovascular #pathophys

Title: Unravelling the interplaybetween #Harmattan wind andbaroreflex functions: implicationon environmental health andcardiovascular #pathophys