3D and 4D printing of biomedical materials: current trends, challenges, and future outlook

Three-dimensional (3D) and four-dimensional (4D) printing have emerged as the next-generation fabrication technologies, covering a broad spectrum of areas, including construction, medicine, transpor

[...] Read more.

Three-dimensional (3D) and four-dimensional (4D) printing have emerged as the next-generation fabrication technologies, covering a broad spectrum of areas, including construction, medicine, transportation, and textiles. 3D printing, also known as additive manufacturing (AM), allows the fabrication of complex structures with high precision via a layer-by-layer addition of various materials. On the other hand, 4D printing technology enables printing smart materials that can alter their shape, properties, and functions upon a stimulus, such as solvent, radiation, heat, pH, magnetism, current, pressure, and relative humidity (RH). Myriad of biomedical materials (BMMs) currently serve in many biomedical engineering fields aiding patients’ needs and expanding their life-span. 3D printing of BMMs provides geometries that are impossible via conventional processing techniques, while 4D printing yields dynamic BMMs, which are intended to be in long-term contact with biological systems owing to their time-dependent stimuli responsiveness. This review comprehensively covers the most recent technological advances in 3D and 4D printing towards fabricating BMMs for tissue engineering, drug delivery, surgical and diagnostic tools, and implants and prosthetics. In addition, the challenges and gaps of 3D and 4D printed BMMs, along with their future outlook, are also extensively discussed. The current review also addresses the scarcity in the literature on the composition, properties, and performances of 3D and 4D printed BMMs in medical applications and their pros and cons. Moreover, the content presented would be immensely beneficial for material scientists, chemists, and engineers engaged in AM manufacturing and clinicians in the biomedical field.

Gayan A. Appuhamillage ... Achintha Wijenayake

Three-dimensional (3D) and four-dimensional (4D) printing have emerged as the next-generation fabrication technologies, covering a broad spectrum of areas, including construction, medicine, transportation, and textiles. 3D printing, also known as additive manufacturing (AM), allows the fabrication of complex structures with high precision via a layer-by-layer addition of various materials. On the other hand, 4D printing technology enables printing smart materials that can alter their shape, properties, and functions upon a stimulus, such as solvent, radiation, heat, pH, magnetism, current, pressure, and relative humidity (RH). Myriad of biomedical materials (BMMs) currently serve in many biomedical engineering fields aiding patients’ needs and expanding their life-span. 3D printing of BMMs provides geometries that are impossible via conventional processing techniques, while 4D printing yields dynamic BMMs, which are intended to be in long-term contact with biological systems owing to their time-dependent stimuli responsiveness. This review comprehensively covers the most recent technological advances in 3D and 4D printing towards fabricating BMMs for tissue engineering, drug delivery, surgical and diagnostic tools, and implants and prosthetics. In addition, the challenges and gaps of 3D and 4D printed BMMs, along with their future outlook, are also extensively discussed. The current review also addresses the scarcity in the literature on the composition, properties, and performances of 3D and 4D printed BMMs in medical applications and their pros and cons. Moreover, the content presented would be immensely beneficial for material scientists, chemists, and engineers engaged in AM manufacturing and clinicians in the biomedical field.

Effects of dietary imbalances of micro- and macronutrients on the ocular microbiome and its implications in dry eye diseaseOpen AccessReviewDry eye disease (DED) is a complex and multifactorial ocular surface disease affecting a large proportion of the population. There is emerging evidence of the impact of the microbiomes of the ocular [...] Read more.Madeline Pilkington ... Kenneth Gek-Jin OoiPublished: February 29, 2024 Explor Med. 2024;5:127–147

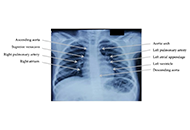

Effects of dietary imbalances of micro- and macronutrients on the ocular microbiome and its implications in dry eye diseaseOpen AccessReviewDry eye disease (DED) is a complex and multifactorial ocular surface disease affecting a large proportion of the population. There is emerging evidence of the impact of the microbiomes of the ocular [...] Read more.Madeline Pilkington ... Kenneth Gek-Jin OoiPublished: February 29, 2024 Explor Med. 2024;5:127–147 Role of chest radiographs and electrocardiograms in predicting the hemodynamics of congenital heart diseaseOpen AccessOriginal ArticleAim: This study aimed to evaluate the role of chest radiographs and electrocardiograms in predicting the hemodynamics of congenital heart disease (CHD). Methods: This retrospective study in [...] Read more.Romila Chimoriya ... Neeraj AwasthyPublished: February 29, 2024 Explor Med. 2024;5:112–126

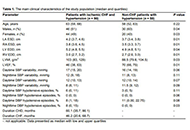

Role of chest radiographs and electrocardiograms in predicting the hemodynamics of congenital heart diseaseOpen AccessOriginal ArticleAim: This study aimed to evaluate the role of chest radiographs and electrocardiograms in predicting the hemodynamics of congenital heart disease (CHD). Methods: This retrospective study in [...] Read more.Romila Chimoriya ... Neeraj AwasthyPublished: February 29, 2024 Explor Med. 2024;5:112–126 The severity of chronic heart failure and the parameters of daily blood pressure profile in patients with coronary heart diseaseOpen AccessOriginal ArticleAim: Although the prevalence of coronary heart disease (CHD) and hypertension which are the most common causes of the development and progression of chronic heart failure (CHF) is high, 24-hour a [...] Read more.Natalia S. Akimova ... Oksana V. BugaevaPublished: February 28, 2024 Explor Med. 2024;5:101–111

The severity of chronic heart failure and the parameters of daily blood pressure profile in patients with coronary heart diseaseOpen AccessOriginal ArticleAim: Although the prevalence of coronary heart disease (CHD) and hypertension which are the most common causes of the development and progression of chronic heart failure (CHF) is high, 24-hour a [...] Read more.Natalia S. Akimova ... Oksana V. BugaevaPublished: February 28, 2024 Explor Med. 2024;5:101–111 Insights on aspects of apoptosis in neurodegenerative disorders: a comprehensive reviewOpen AccessReviewNerve cell death is the central aspect of human neurodegenerative disorders. Neuronal death in results leads to the onset of various human neurological disorders such as Alzheimer’s disease, Parki [...] Read more.Rajat Goyal ... Mohammad Amjad KamalPublished: February 28, 2024 Explor Med. 2024;5:89–100

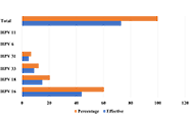

Insights on aspects of apoptosis in neurodegenerative disorders: a comprehensive reviewOpen AccessReviewNerve cell death is the central aspect of human neurodegenerative disorders. Neuronal death in results leads to the onset of various human neurological disorders such as Alzheimer’s disease, Parki [...] Read more.Rajat Goyal ... Mohammad Amjad KamalPublished: February 28, 2024 Explor Med. 2024;5:89–100 Prevalence of specific human papillomavirus genotypes among Moroccan women with invasive cervical cancerOpen AccessOriginal ArticleAim: The aim of this study is to investigate the prevalence of human papillomavirus (HPV) genotypes in Moroccan women diagnosed with invasive cervical cancer and to assess the association between [...] Read more.Kaoutar Anouar Tadlaoui ... Moulay Mustapha EnnajiPublished: February 28, 2024 Explor Med. 2024;5:76–88

Prevalence of specific human papillomavirus genotypes among Moroccan women with invasive cervical cancerOpen AccessOriginal ArticleAim: The aim of this study is to investigate the prevalence of human papillomavirus (HPV) genotypes in Moroccan women diagnosed with invasive cervical cancer and to assess the association between [...] Read more.Kaoutar Anouar Tadlaoui ... Moulay Mustapha EnnajiPublished: February 28, 2024 Explor Med. 2024;5:76–88 Cell culture models for epilepsy research and treatmentOpen AccessReviewAcquired or hereditary epilepsy affects millions of people. Today, the disease is pharmacoresistant in about 30 percent of cases, meaning that the seizures do not come under acceptable control in re [...] Read more.Ilya Oblasov ... Evgeny NikitinPublished: February 25, 2024 Explor Med. 2024;5:65–75

Cell culture models for epilepsy research and treatmentOpen AccessReviewAcquired or hereditary epilepsy affects millions of people. Today, the disease is pharmacoresistant in about 30 percent of cases, meaning that the seizures do not come under acceptable control in re [...] Read more.Ilya Oblasov ... Evgeny NikitinPublished: February 25, 2024 Explor Med. 2024;5:65–75 Navigating breast health: a comprehensive approach to atypical ductal hyperplasia of the breast management and surveillanceOpen AccessMini ReviewAtypical ductal hyperplasia (ADH) is a benign lesion of the breast that is associated with an increased risk of invasive breast cancer. This review explores the pathophysiology, risk factors for pro [...] Read more.Nadia Islam, Suneela VeguntaPublished: February 07, 2024 Explor Med. 2024;5:59–64

Navigating breast health: a comprehensive approach to atypical ductal hyperplasia of the breast management and surveillanceOpen AccessMini ReviewAtypical ductal hyperplasia (ADH) is a benign lesion of the breast that is associated with an increased risk of invasive breast cancer. This review explores the pathophysiology, risk factors for pro [...] Read more.Nadia Islam, Suneela VeguntaPublished: February 07, 2024 Explor Med. 2024;5:59–64 Cannabidiol, cognition and schizophrenia: a narrative reviewOpen AccessReviewSchizophrenia is a serious mental disorder affecting about 1% of the population. It is characterised by multiple symptoms which are mostly responsive to treatment with antipsychotic medications. Cog [...] Read more.Trevor R. NormanPublished: February 07, 2024 Explor Med. 2024;5:48–58

Cannabidiol, cognition and schizophrenia: a narrative reviewOpen AccessReviewSchizophrenia is a serious mental disorder affecting about 1% of the population. It is characterised by multiple symptoms which are mostly responsive to treatment with antipsychotic medications. Cog [...] Read more.Trevor R. NormanPublished: February 07, 2024 Explor Med. 2024;5:48–58 3D and 4D printing of biomedical materials: current trends, challenges, and future outlookOpen AccessReviewThree-dimensional (3D) and four-dimensional (4D) printing have emerged as the next-generation fabrication technologies, covering a broad spectrum of areas, including construction, medicine, transpor [...] Read more.Gayan A. Appuhamillage ... Achintha WijenayakePublished: February 06, 2024 Explor Med. 2024;5:17–47

3D and 4D printing of biomedical materials: current trends, challenges, and future outlookOpen AccessReviewThree-dimensional (3D) and four-dimensional (4D) printing have emerged as the next-generation fabrication technologies, covering a broad spectrum of areas, including construction, medicine, transpor [...] Read more.Gayan A. Appuhamillage ... Achintha WijenayakePublished: February 06, 2024 Explor Med. 2024;5:17–47 The most suitable system to grind the whole tooth to use it as graft materialOpen AccessOriginal ArticleAim: In regenerative dentistry, the success is influenced by the graft material, which should act as an osteoconductive scaffold. It provides a mineral substrate during resorption and induces the [...] Read more.Elio Minetti ... Francesco InchingoloPublished: February 06, 2024 Explor Med. 2024;5:1–16

The most suitable system to grind the whole tooth to use it as graft materialOpen AccessOriginal ArticleAim: In regenerative dentistry, the success is influenced by the graft material, which should act as an osteoconductive scaffold. It provides a mineral substrate during resorption and induces the [...] Read more.Elio Minetti ... Francesco InchingoloPublished: February 06, 2024 Explor Med. 2024;5:1–16